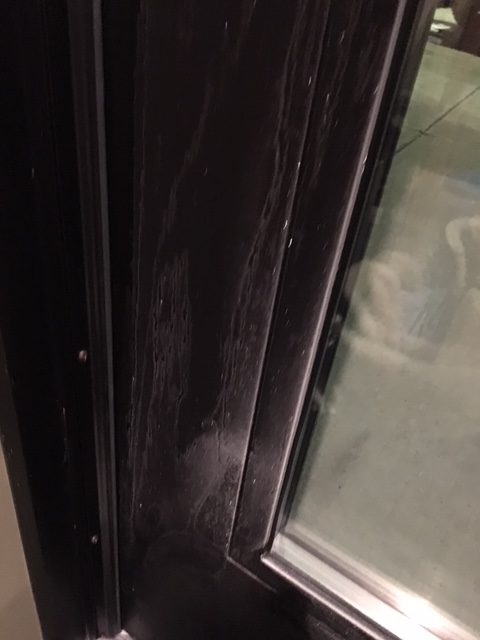

Condensation

The issue of condensation and frost on the interior surfaces of architectural aluminum framing arises seasonally when outdoor temperatures reach extreme lows. Thermally “broken” systems reduce the effects of cold temperatures, but high humidity levels found in residential and some commercial buildings accentuate condensation.

The following links to information and documents provided by The American Architectural Manufacturer’s Association help to explain the conditions that cause condensation, and provide information on further reducing it.

ASHRAE 99.6%

HDB Temperature (°F)

Major U.S. Cities and State Capitals

Values that represent dry-bulb temperatures corresponding to 99.6% annual cumulative frequency of occurrence (cold conditions), °F.

Understanding Indoor

Condensation in Your Home

AAMA started evaluating the thermal performance of windows and doors in 1972. The first AAMA voluntary standard for thermal performance was developed specifically to measure the condensation resistance of windows and sliding glass doors. Since that time, AAMA standards have evolved to include windows and doors of various materials and types, as well as ensuring that emerging technologies are assessed.

As an association of window, door and skylight manufacturers, AAMA understands that these products enhance the beauty and comfort of your home by providing views, ventilation and daylight. To maximize the enjoyment and realization of these attributes, you should understand how condensation is formed and how it can be minimized.

Condensation Resistance

Factor Tool

The CRF Tool is intended to provide general guidance on suggesting a minimum Condensation Resistance Factor (CRF) based on a project-specific set of environmental conditions.

While not an absolute value, the CRF is a rating number obtained under specified test conditions to allow a relative comparison of the condensation performance of the product. It will provide a comparative rating of similar products of the same configuration and permit the determination of the conditions beyond which an objectionable amount of condensation may occur.

Condensation

The issue of condensation and frost on the interior surfaces of architectural aluminum framing arises seasonally when outdoor temperatures reach extreme lows. Thermally “broken” systems reduce the effects of cold temperatures, but high humidity levels found in residential and some commercial buildings accentuate condensation.

The following links to information and documents provided by The American Architectural Manufacturer’s Association help to explain the conditions that cause condensation, and provide information on further reducing it.

ASHRAE 99.6%

HDB Temperature (°F)

Major U.S. Cities and State Capitals

Values that represent dry-bulb temperatures corresponding to 99.6% annual cumulative frequency of occurrence (cold conditions), °F.

Understanding Indoor

Condensation in Your Home

AAMA started evaluating the thermal performance of windows and doors in 1972. The first AAMA voluntary standard for thermal performance was developed specifically to measure the condensation resistance of windows and sliding glass doors. Since that time, AAMA standards have evolved to include windows and doors of various materials and types, as well as ensuring that emerging technologies are assessed.

As an association of window, door and skylight manufacturers, AAMA understands that these products enhance the beauty and comfort of your home by providing views, ventilation and daylight. To maximize the enjoyment and realization of these attributes, you should understand how condensation is formed and how it can be minimized.

Condensation Resistance

Factor Tool

The CRF Tool is intended to provide general guidance on suggesting a minimum Condensation Resistance Factor (CRF) based on a project-specific set of environmental conditions.

While not an absolute value, the CRF is a rating number obtained under specified test conditions to allow a relative comparison of the condensation performance of the product. It will provide a comparative rating of similar products of the same configuration and permit the determination of the conditions beyond which an objectionable amount of condensation may occur.